Discover our latest brochures!

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

Our Traditional patent glazing system remains our customers’ most popular choice for use on unheated spaces such as railway stations, glazed canopies and covered ways where thermal properties are not a primary consideration. This system has been installed on thousands of projects nationwide, demonstrating its widespread acceptance and reliability. It is available with a choice of capping systems to suit a variety of aesthetic and functional needs, offering versatility alongside its robust performance.

A truly great glazing system, the Traditional patent glazing system combines economy with a proven track record of success. In recent years alone, we have installed over 40,000m² of this system on many major railway stations throughout the UK. This extensive application highlights its durability and effectiveness in high-traffic environments.

The system’s enduring popularity is a testament to its quality and reliability, making it an ideal choice for numerous architectural projects. Whether for large-scale infrastructure or smaller installations, our Traditional patent glazing system delivers outstanding performance and value.

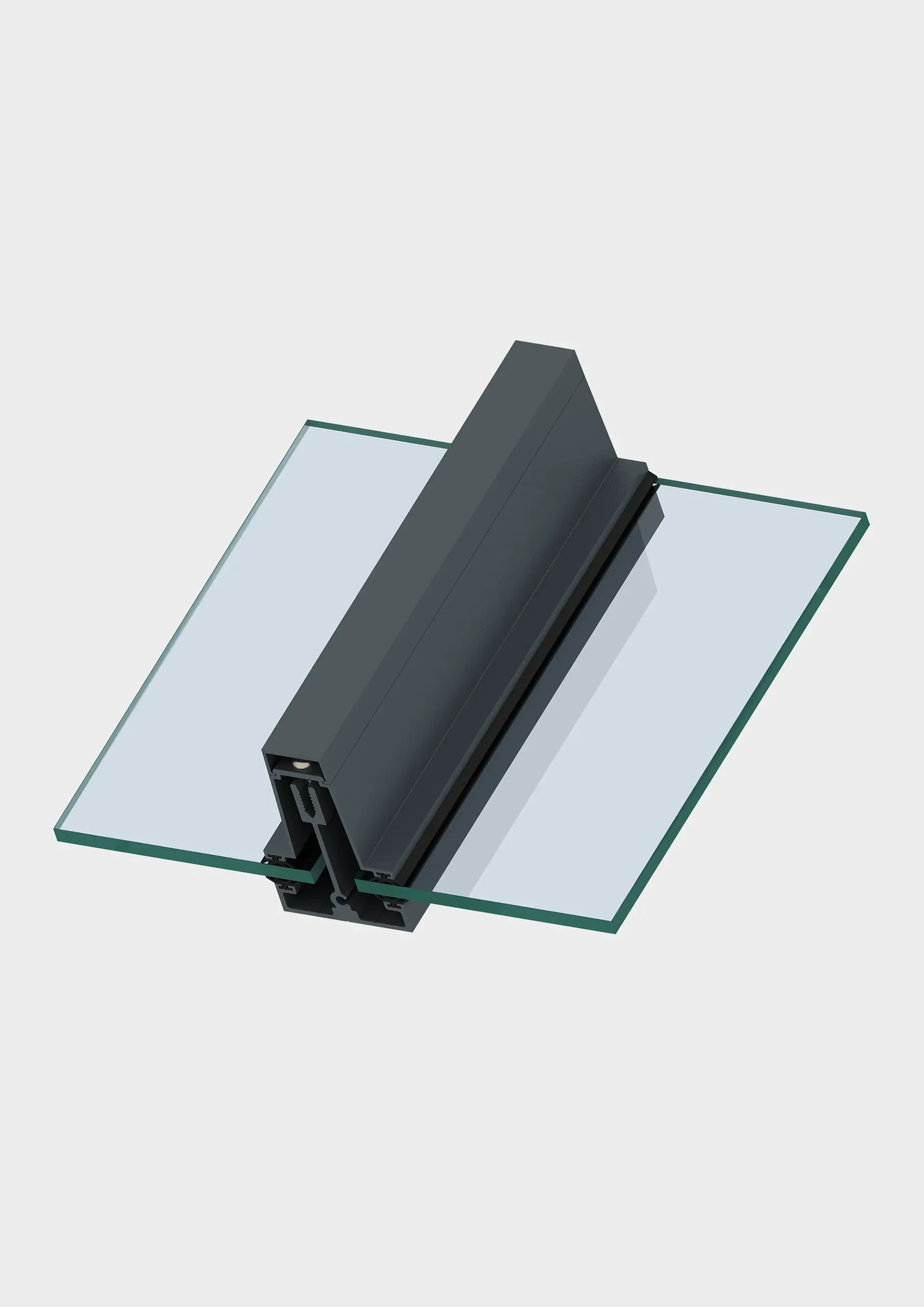

Our Traditional patent glazing bars are designed to receive single glazing of any thickness and are also suitable for accommodating solid and multi-wall polycarbonate sheets up to 30mm thick. It is possible to incorporate double glazed units into this range of glazing bar when compliance with Building Regulations Document L is not a requirement.

The glazing bar is an inverted ‘T’ design and its strength is provided by the external stalk (or web). The outer surface can be weathered by a choice of extruded aluminium screw-on and snap-on cappings or extruded aluminium screw-on wings.

This system is an upgraded design to our BL Traditional range which has been installed on thousands of projects nationwide. It is available in a range of three glazing bars to achieve light spans as well as large unsupported spans up to 5560mm.

A truly great glazing system combined with economy and a proven track record. 40,000m² of this glazing system has been installed by us on many major railway stations throughout the UK in recent times.

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

Performance Data for Traditional patent glazing bars

The glazing bar spans shown above are based on using 6mm thick glass for the double glazed, single glazed and canopy types and the bars being spaced at 600mm centres. We will select the appropriate glazing bar for each contract. Spans are dependent upon the site location and exposure rating, site altitude, distance from the sea, height of glazing from ground level, shape of the roof, pitch of glazing, glazing bar centres, glass weight, wind speeds, snow load, dead load and maintenance loads.

* The above spans for each glazing bar have two values. The lower span values are calculated using the most extreme environmental loadings possible in the UK whereas the higher span values are based on the least extreme. Due to the wide range of these values it is therefore essential that we are supplied with the site postal code to enable us to calculate the correct glazing bar type for every project. There are a large number of variables which are used to determine the maximum span of the glazing bars so please do not attempt to buy any glazing bar materials from us without us first allowing us to carry out the necessary calculations for your project.

Click the links below to view our 2D drawings, 3D renders, H10 Specifications and Brochure to help you develop and visualise your roof glazing project.

Traditional patent glazing is a cost-effective glazing system designed for unheated spaces such as railway stations, canopies and covered walkways. It provides durable, reliable single-glass or polycarbonate solutions with a proven track record nationwide.

Traditional glazing bars are suitable for railway stations, covered ways, canopies, skylights and other unheated spaces where thermal performance is not critical. They are ideal for projects that require durable, economical glazing solutions.

Yes. The system is designed to accept solid and multiwall polycarbonate sheets up to 30mm thick, in addition to single glazing of any thickness. Double glazing can also be used when Building Regulations compliance is not required.

Traditional glazing bars have an inverted ‘T’ design with strong external webs, multiple capping options and high tolerance for structural discrepancies. With over 40,000m² installed across UK stations, the system is proven for long-term durability.