Patent glazing has an excellent record of public safety over many years. All of our patent glazing systems can be supplied with a glazed infill to meet non-fragility ratings.

Appropriate Glass Types

Safety First

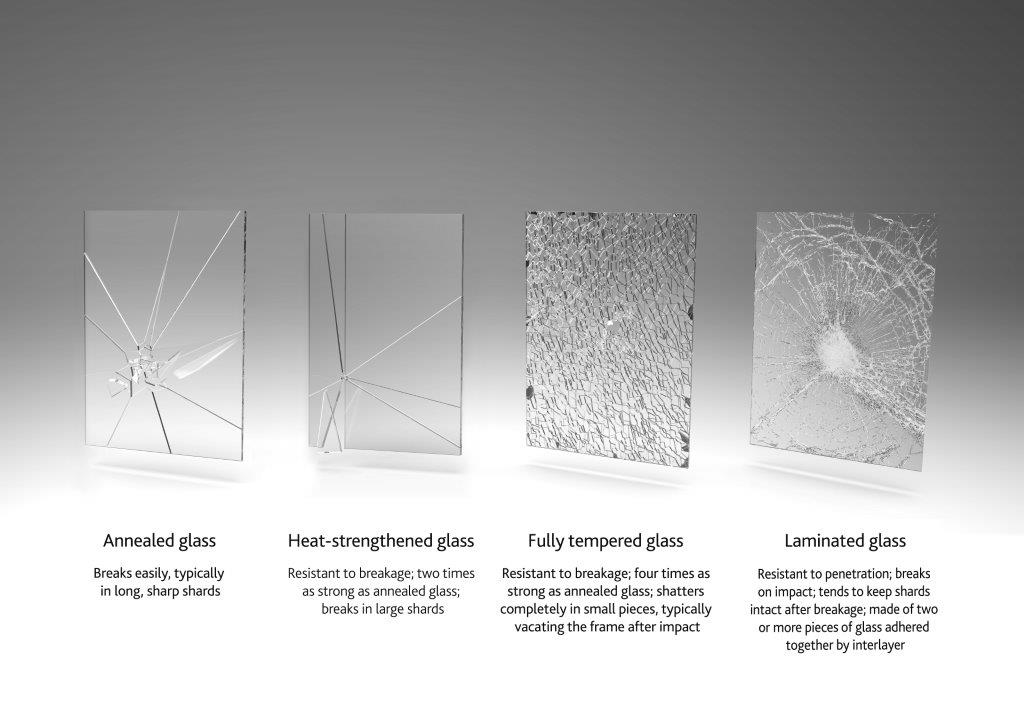

When installing glass in sloped patent glazing settings, it’s crucial to use materials designed to minimise harm in case of breakage. Laminated safety glass, for instance, is engineered to hold its form if cracked, while toughened safety glass shatters into small, blunt pieces that reduce the risk of injury compared to the sharp fragments of standard annealed glass.

Regulatory and guidance documents, such as BS 5516: 2004 for vertical and sloping patent glazing, CWCT TN112 and BS6262:2018, provide key recommendations on suitable glass types for roofing applications.

For single-pane installations, BS 5516 advises using either laminated or toughened glass, while in double glazing setups, the lower pane should always consist of one of these safety glass types.

In cases where the lower pane of a double-glazed unit is toughened, BS 5516 further advises using an approved safety glass for the upper pane as well.

Suitable Glass Type

Suitable glass type for height of roof glazing from floor level

Height from floor |

Single Glazing |

Double and Triple Glazing |

|---|---|---|

0-5m (A) |

(A) Toughened Glass or Laminated Glass |

(A) The lower pane should be Toughened or Laminated. If the lower pane is toughened glass then the upper pane should be Toughened also. * |

>5m (B) |

(B) Toughened Glass with Safety Film, Laminated, Heat Strengthened Laminated Glass or Toughened Laminated Glass with Specialist Ionoplast Interlayer |

(B) The lower pane should be Toughened with Safety Film, Laminated Heat Strengthened Laminated glass or Toughened Laminated Glass with Specialist Ionoplast Interlayer. If the lower pane is toughened glass then the upper pane should be Toughened. * |

PLEASE NOTE:

Wired glass is no longer recommended for roof glazing, as it does not meet the current safety standards outlined in BS EN 12600.

Moreover, standard toughened laminated glass is not advisable for roofing when it includes a standard PVB (polyvinyl butyral) interlayer, as noted in CWCT TN112. While toughened glass typically shatters into small, harmless pieces, in a laminated setup, these fragments adhere to the PVB layer, causing the entire pane to sag. This sagging can create a single, large sheet that risks detaching and potentially causing significant injury. However, toughened laminated glass can be safely used in roof applications if a specialised SGP (SentryGlas Plus) Ionoplast interlayer replaces the PVB. SGP interlayers are notably more robust, being five times stronger and a hundred times stiffer than PVB, helping the pane maintain its integrity in the event of damage.

For additional details or alternative solutions, please don’t hesitate to contact us.

It’s important to avoid using toughened glass as single glazing or as the lower pane in double or triple-glazed units positioned above swimming pools, as any glass fragments from a breakage could enter pool pumps and potentially cause costly damage.

When close-fitting blinds are installed directly beneath roof glazing, annealed laminated glass is generally unsuitable due to the risk of thermal stress. In such cases, a better option would be toughened glass with a factory-applied safety film, or, for greater durability, a heat-strengthened laminated glass.

Glass recommendations for Sloping Patent Glazing

Historically, a 6mm thickness has been standard for glass in sloping patent glazing installations. This thickness remains the most widely used across projects, with patent glazing’s strong safety track record confirming 6mm as both a safe and effective choice for public safety. For applications involving roof access, however, using thicker glass can further reduce the risk of breakage and provide additional safety, especially when barriers aren’t present to prevent falls onto the glass from above.

Given the relatively narrow panes used in patent glazing, increasing thickness beyond 6mm is rarely necessary for supporting expected loads. However, since patent glazing is usually installed at a slope, it may be worth assessing the risk of falling glass and, depending on the location, considering additional protective measures for public safety in case of a breakage.

As indicated in the table above, using toughened glass alone as the inner pane in sloping glazing is not advised if it is positioned more than 5 meters above ground level. If breakage occurs from such a height, the dice-like fragments can pose a greater risk of injury compared to glass installed at lower heights.

To enhance safety in these situations, the inner pane should be made of toughened glass with an applied safety film, annealed laminated glass or heat-strengthened laminated glass. These options help prevent broken glass from falling into the building below in the event of a fracture.

Non-Fragility and Patent Glazing

The British Standards for glass safety, specifically BS6262 Part 4, provides recommendations on selecting appropriate safety glass, as outlined in the table above. Together with BS5516 and CWCT TN112, these standards focus on safeguarding the public from injuries related to glass breakage or failure in roof glazing installations.

Recently, increased attention has been given to protecting workers who perform tasks on rooftops. Every year, preventable fatalities occur from individuals falling through fragile roofing materials. Many of these incidents involve in-plane rooflights made of plastic or polycarbonate that were accidentally walked on, resulting in falls. Other incidents involve individuals falling from an upper roof level onto fragile surfaces below.

With patent glazing systems, accidental entry onto the roof is highly unlikely. Furthermore, if there is any risk of individuals falling from a higher roof level onto a patent glazing system, building designers typically incorporate edge barriers on the upper level to prevent such falls. These safety measures contribute to patent glazing’s strong safety record.

Two distinct non-fragility testing standards exist for roofing materials. The Advisory Committee for Roof Work has published ACR[M]001:2014 Test for Non-Fragility of Large Element Roofing Assemblies, 5th Edition (the “Red Book”). Additionally, The Centre for Window and Cladding Technology developed a separate standard, TN 67 Safety and Fragility of Overhead Glazing: Testing and Assessment.

Over recent years, these tests have been developed to help reduce the number of fatalities and injuries related to falls through fragile roofing materials. Increasingly, architects are specifying patent glazing systems that have achieved a non-fragile classification under one or both of the test criteria mentioned above.

We are pleased to share that several of our patent glazing systems have undergone independent testing for non-fragility compliance, achieving high marks and being classified as non-fragile assemblies. Recognizing the evolving standards in non-fragility testing, we installed our own steel-framed test rig at our Dewsbury facility. This allows us to conduct frequent testing on our patent glazing systems as needed. The diverse configurations of patent glazing, determined by factors such as span, glazing bar spacing, glazing slope, glass type, and system design, require test-based validation for each unique setup.

A prime example of this rigorous testing and compliance can be seen in our project at Victoria Coach Station, where 9.5mm laminated safety glass was used and independently tested to meet CWCT TN66 & TN67 standards.

Our extensive testing confirms that all our patent glazing systems can meet non-fragility standards under the ACRM and CWCT tests when installed at any slope with a maximum span of 3 meters, pane width of up to 750mm, and laminated glass of at least 8.8mm thickness. In double-glazed testing, we used outer panes of 6mm toughened glass paired with an 8.8mm laminated inner pane. While non-fragility ratings may be possible with thinner glass in specific situations, we generally recommend using robust materials for optimal safety.