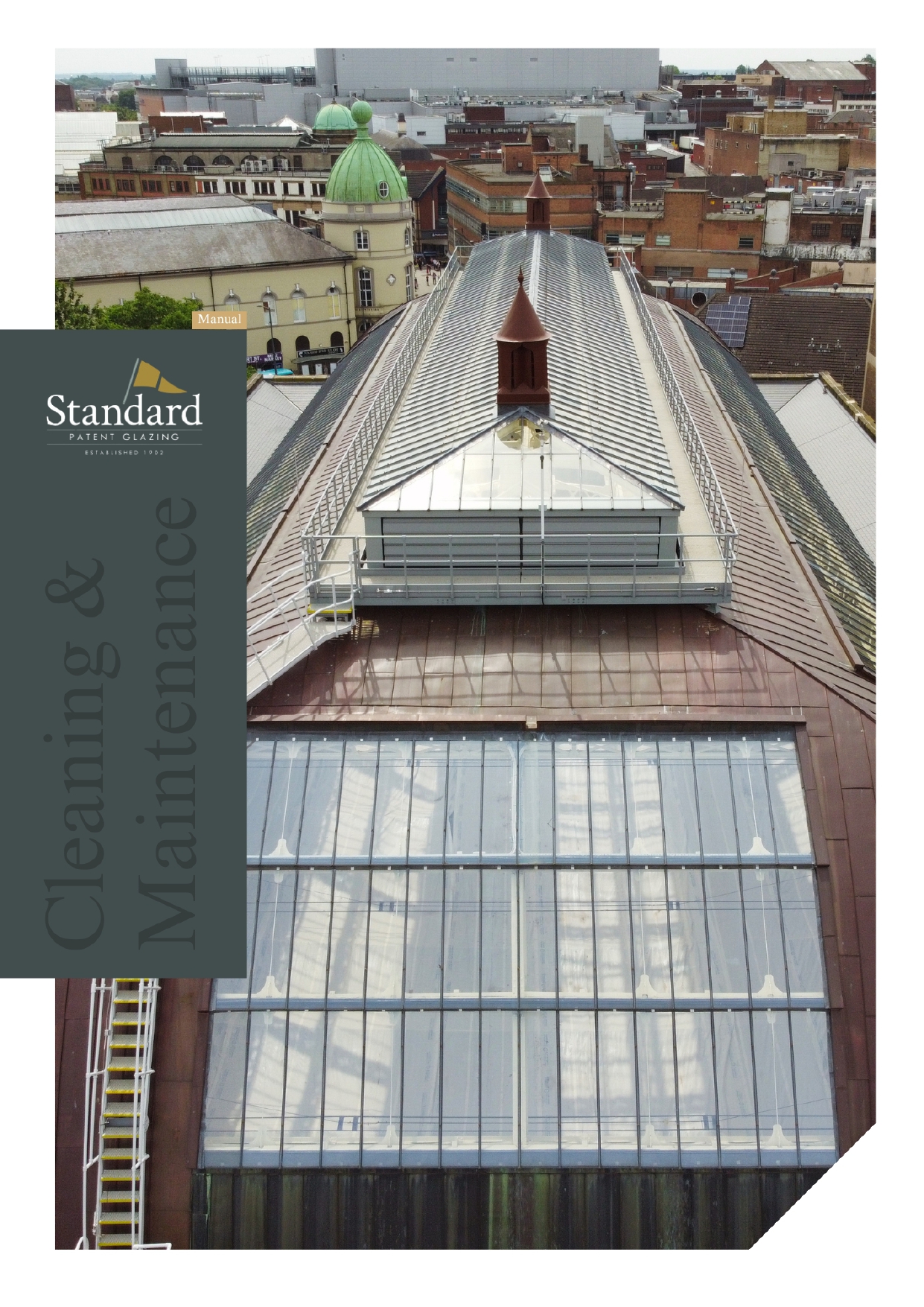

Cleaning and maintenance are essential to extending the lifespan of your roof patent glazing system. To ensure this is done safely and effectively, it should be carried out by qualified individuals or organisations. Our Cleaning and Maintenance Manual provides comprehensive guidelines and procedures to help you effectively clean and maintain our glazing systems, ensuring they remain in excellent condition for years to come.

Cleaning & Maintenance

Downloads

Periodic cleaning of the glazing to remove dirt and the build up of debris will be required to keep the glazing system in a good order and to avoid the loss of light transmission from the glass. Certain glass products can be subjected to thermal stresses if the panes are left unclean for prolonged periods of time.

Aluminium sections with powder coated or anodised finishes must also be cleaned regularly to conform to the terms of guarantee.

Under the Construction (Design and Management) Regulations 2015, the designers of the building have a responsibility to design-in access, at the initial and early design stages, for the roof glazing cleaning and maintenance requirements of the completed project.

Maintenance managers and operatives must refer back and consult the “Health and Safety File” and an appropriate Method Statement/Risk Assessment for guidance on access, routes for foot traffic, safety requirements and the use of all necessary personal protection equipment, prior to any work being carried out.

“The commitment to Health and Safety has been underpinned by the company’s efforts on training across the workforce. This has included NEBOSH, SMSTS, SSSTS, PTS & CSCS. We are understandably very proud to have been the company awarded with the prestigious title ‘Best Health and Safety Performance’.”

Award for Best Safety Performance for Less than 50 employees