All patent glazing systems must be installed with suitable safety glass types. These are either toughened or laminated glass or a combination of both for double and triple glazed systems.

The Common Glass Types

Toughened Safety Glass

Toughened safety glass (sometimes called tempered glass) is produced by heating annealed glass to approximately 620ºC, at which point it begins to soften. The surfaces of this heated glass are then cooled rapidly. The technique creates a state of high compression in the outer surfaces of the glass and, as a result, although most other characteristics remain unchanged, the bending strength is increased by a factor of up to five times that of annealed glass.

When broken, the toughened glass fractures into small pieces (called dice). As these particles do not have the sharp edges and dagger points of broken annealed glass, it is generally regarded as a safety glass. While these dice may cause minor cuts, it is very difficult to cause a severe injury with them, provided the fragments are small enough.

Toughened safety glass must be cut to size and have any other processing, such as edge polishing or hole drilling, completed before toughening, because attempts to “work” the glass after toughening will cause it to shatter. 6mm toughened glass has a safety rating of class 1-C-2 in accordance with BS EN 12600.

Laminated Safety Glass

Laminated glass consists of one or more panes of glass attached to and separated from each other by means of interlayer materials. Laminated glass is usually made from annealed glass, although it can also be manufactured using toughened, heat strengthened or wired glass. It is no stronger than the glass it is made from and cracks as easily. However, when laminated glass breaks, the glass fragments tend to adhere to the interlayer material.

Although the glass itself maybe annealed glass, on breaking any sharp cutting edges are not generally exposed. The performance of the glass depends very much on the type of interlayer, and there are many different types. The most common interlayer is PVB (polyvinylbutyral) sheet, which usually sticks to the glass very well and produces a uniform thickness, high energy absorbing interlayer.

6.4mm thick laminated glass obtains a Class 2-B-2 safety rating to BS EN 12600, 6.8mm thick laminated glass obtains a lass 1-B-1 safety rating to BS EN 12600. All laminated glass with a PVB interlayer at least 0.8mm thick obtain a Class 1-B-1 safety rating to BS EN 12600.

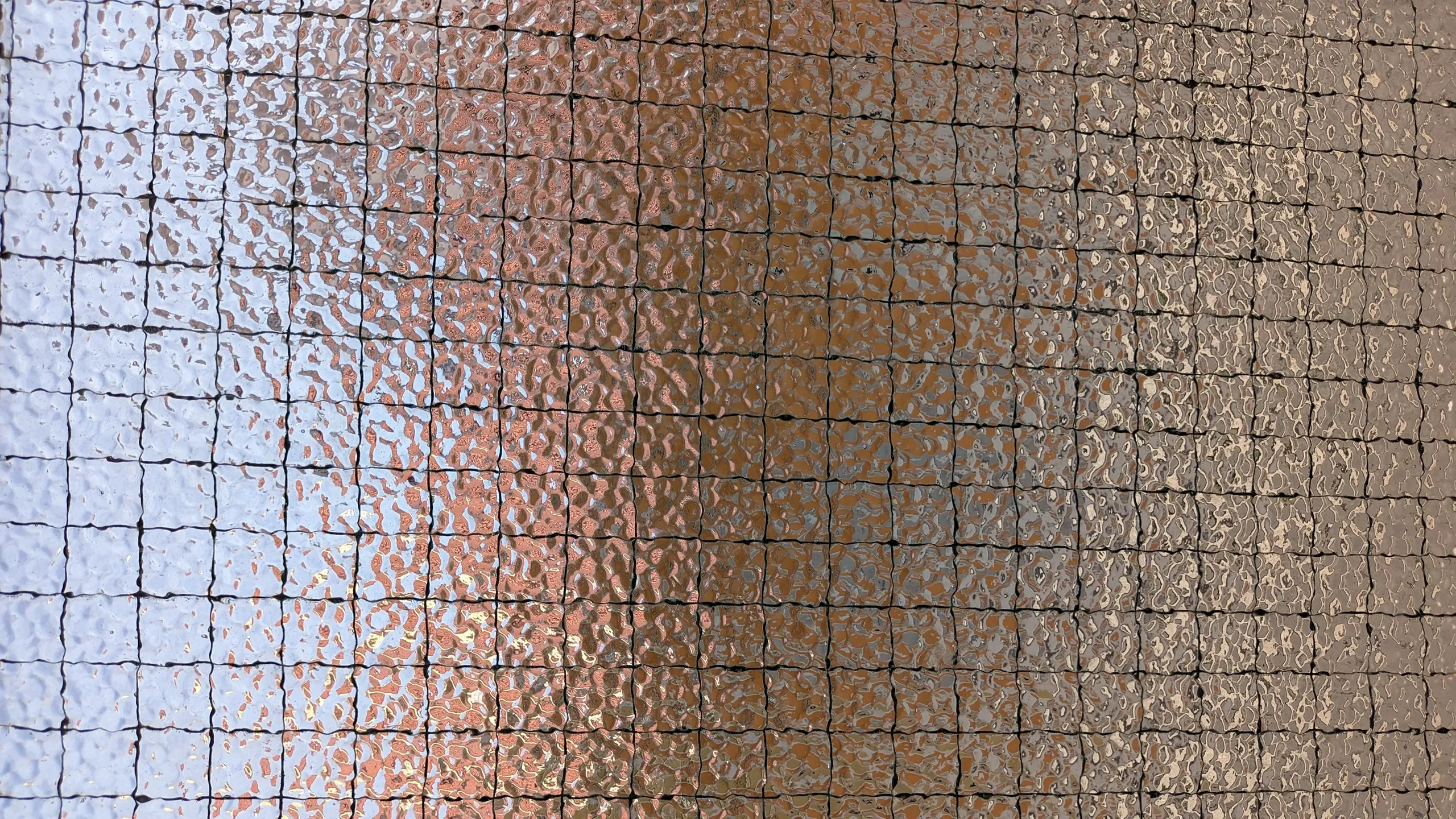

Wired Safety Glass

This is a product which has been regarded as a safety glass type for many, many years. The wires in wired glass tend to hold the glass together when it is cracked. They perform this function admirably when used in roof glazing and, most particularly, in providing fire resistance.

The Cast/textured type supplied by Pilkington Glass has thinner wires than the polished/clear type and therefore no longer carries a safety rating to BS EN 12600. The Polished/Clear type is supplied by Pilkington Glass with normal and thicker wires so the latter product provides a safety Class 3-B-3 rating to BS EN 12600.