Flexibility and Constraints in Modern Patent Glazing Systems.

Glazing Bar Spacings

Historically, patent glazing systems featured glazing bar spacings at approximately 600mm centres. This traditional dimension was widely used but it is not a rigid standard, and the spacing can be varied significantly depending on the specific requirements of a project.

While the 600mm centre spacing provided a reliable guideline, modern advancements in glazing technology and materials have allowed for much greater flexibility. The possible width of the glazing bar centres is influenced by several key factors, which are typically specific to each project. These factors include the type and thickness of the glass used, the overall size and design of the glazing installation, structural support requirements and safety considerations.

Project-specific constraints play a crucial role in determining the optimal spacing for patent glazing bars. For instance, larger glass panes may require wider spacing to reduce the number of visible bars and create a more seamless appearance. However, wider spacing also demands stronger support structures and potentially thicker or more robust glass to ensure safety and durability.

Additionally, advancements in glazing materials and techniques have introduced new possibilities for customising the spacing of glazing bars. Innovations such as toughened glass, laminated compositions, and anti-shatter films enable more extensive and flexible design options while maintaining the necessary structural integrity and safety standards.

For those interested in exploring the full potential of modern patent glazing systems and understanding the constraints that influence glazing bar spacing, please read on for more detailed information and guidelines specific to your project needs. Our expert team is also available to provide personalised advice and solutions to achieve the best results for your design intent.

At the dawn of the patent glazing era, a consistent production of glass had evolved at a dependable width and glazing bar centres have historically remained at this width since (approximately 600mm centres or 2 foot). Conveniently, a 600mm wide pane of glass or double glazed unit up to 3000mm long can usually be carried safely and practically by two or three site personnel using manual lifting techniques with hand held suction lifters, and this rule of thumb for the optimum width remains today.

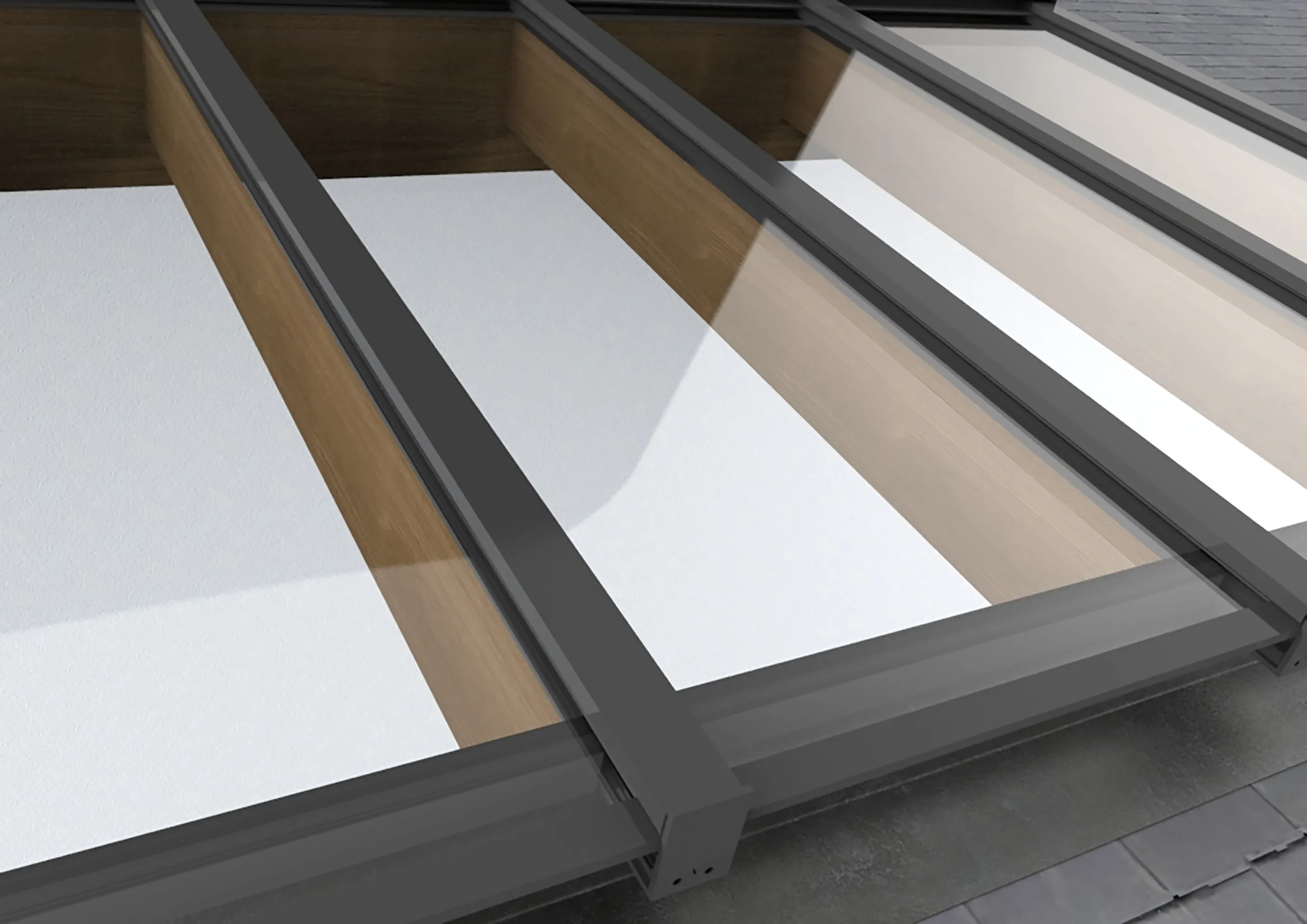

Wider centres than 600mm can be used on patent glazing, but consideration must be given to the logistics of high quality access, provision of mechanical hoisting equipment and future repairs/replacement which could become extremely costly if craneage is the only solution after building handover has occurred.

Under CDM the designer has a responsibility to specify suitable products to enable a project to be executed safely. It is therefore important that the patent glazing contractor is approached early on in the design stage to discuss the practicalities of using glazing panels with large widths.

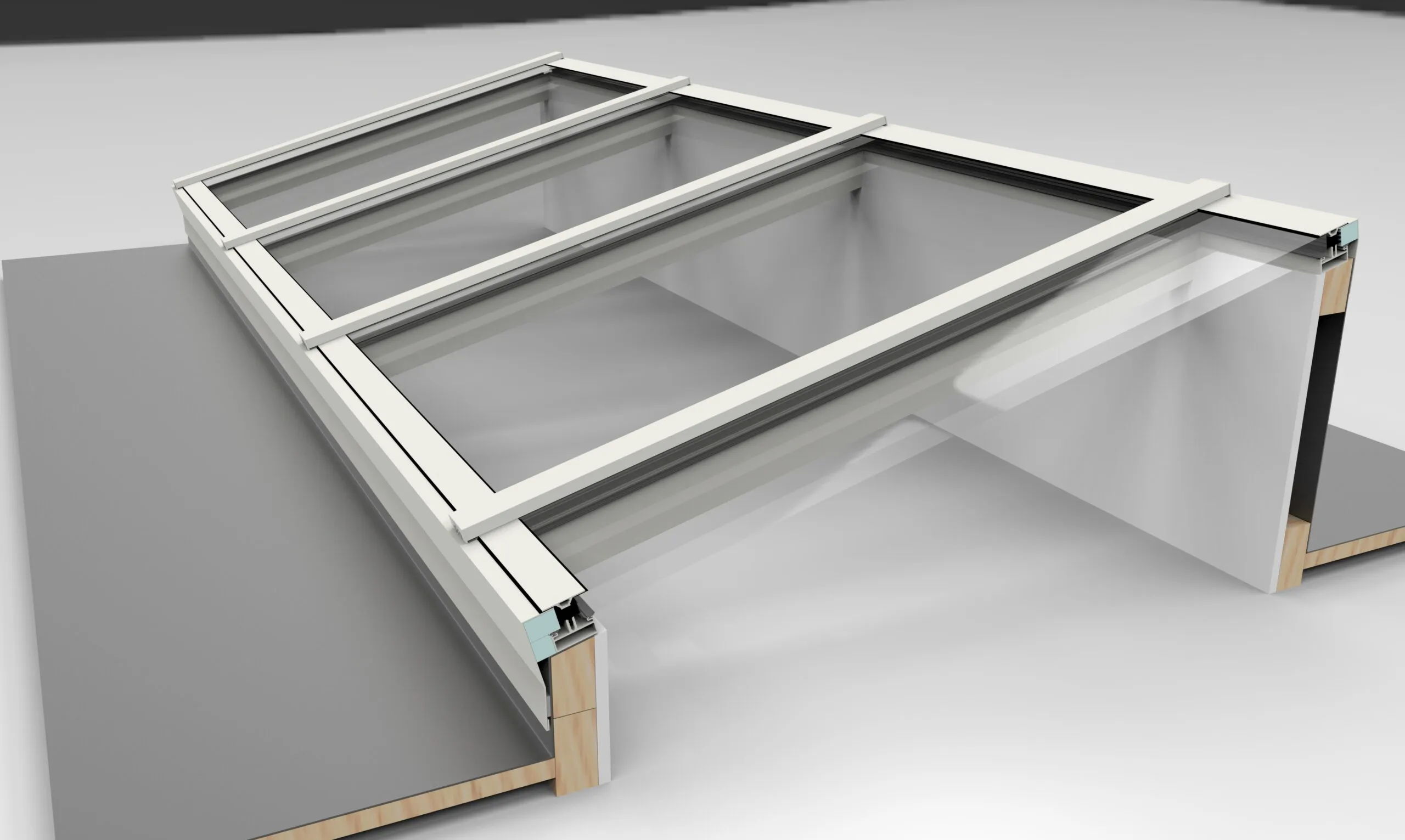

Our two-edge supported patent glazing systems, including Skyline, Skyline Box, and Rafterline, can space glazing bars up to 1000mm wide with suitable glass. However, this is typically limited to glass lengths of up to 2000mm or a glass pane area of 2m² when mechanical hoisting is not available. For larger panes, our four-edge supported system, 4Edge Pro, can accommodate sizes exceeding this criteria. However, panes larger than 2m² often require costly mechanical hoisting or contract lifts for safe installation.

We advise against using 6.4mm laminated glass in sloping patent glazing with centres over 650mm due to the risk of mechanical breakage with such a fragile product. For wider centres, we recommend toughened glass with an optional factory-fitted anti-shatter film, thicker annealed laminates, or specially heat-strengthened laminated compositions.